About Our Floor Sign Stickers | Floor Decals

Indoor Use - Hard Surfaces (FLOORTEX Ultra Non-Slip Floor Vinyl)

- Floor Stickers Made in Australia - Printed within 24 hrs in our facility

- Interior ground stickers use only - up to six months, depending on traffic conditions.

- 250µ textured vinyl

- Unique printable heavy textured surface for non-slip walk areas

- Thick film ensures easy application and removal

- CSIRO slip-resistance tested to AS4586:2013

- Clean removability for up to 6 months

- Print and go – no laminate required

- Suitable for short term floor promotions on all hard surfaces such as vinyl, tiles, timber and timber veneer.

- Ultimate advertising solution in retail and exhibition situations.

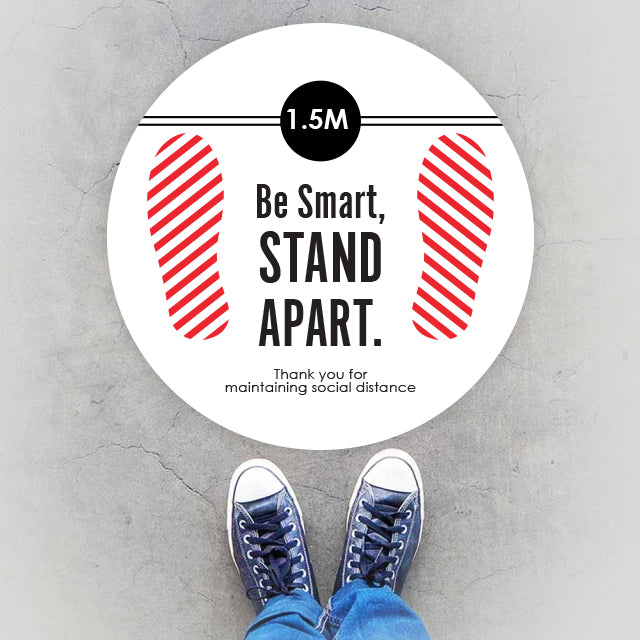

Outdoor Use - Hard Surface (AT13 Heavy Textured)

- Perfect for exterior use.

- 290μ material and a matte white vinyl coating

- Highly conformable without shrinkage or memory

- High traffic for up to 3 months, low traffic for up to 6 months

- Drive-over tough - no lamination required.

- AS 4586-2013 NATA Slip-Rated R11 approved non-slip surface

- No over-lamination required

- Fast installation and removal

- Brilliant print quality with superb results

- Suitable for applications to asphalt, unpainted concrete, textured and low surface-energy situations.

- Ideal for applications such as fast food and liquor drive-thrus, shop entryways, footpaths, bike paths and transit platforms.

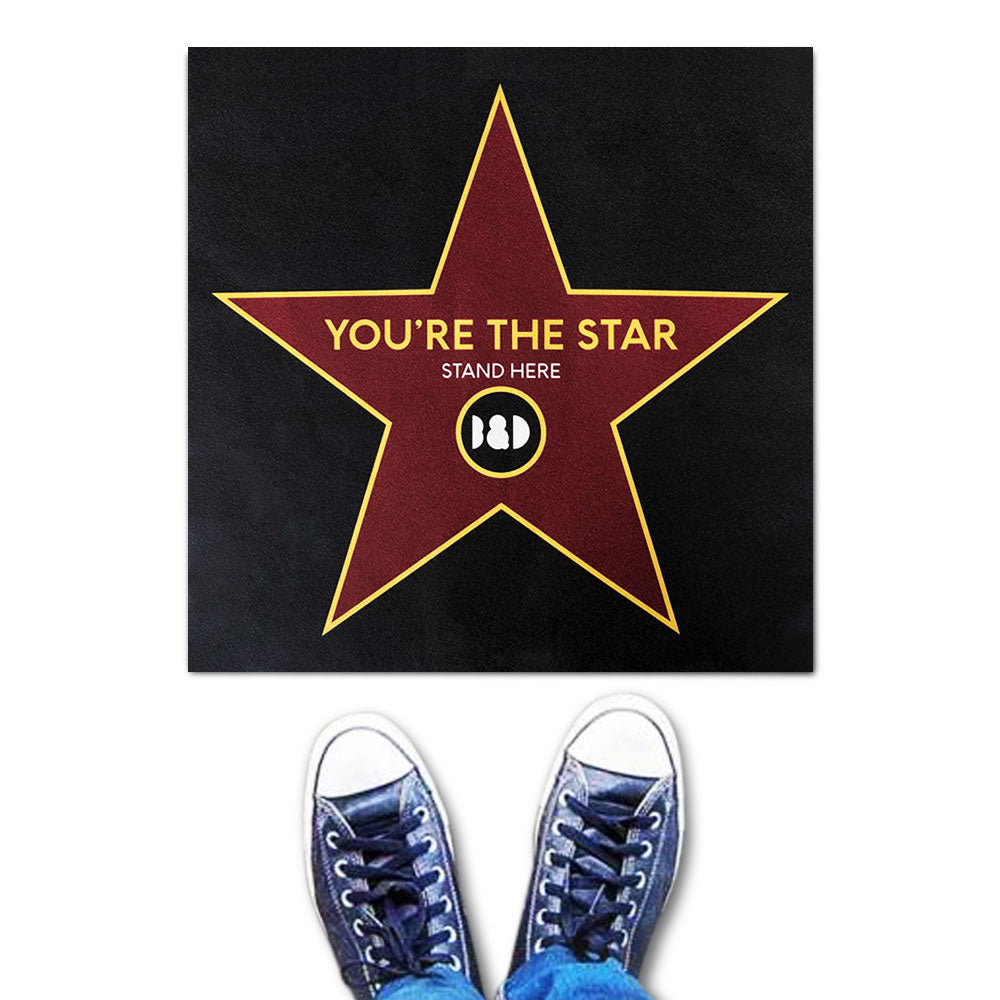

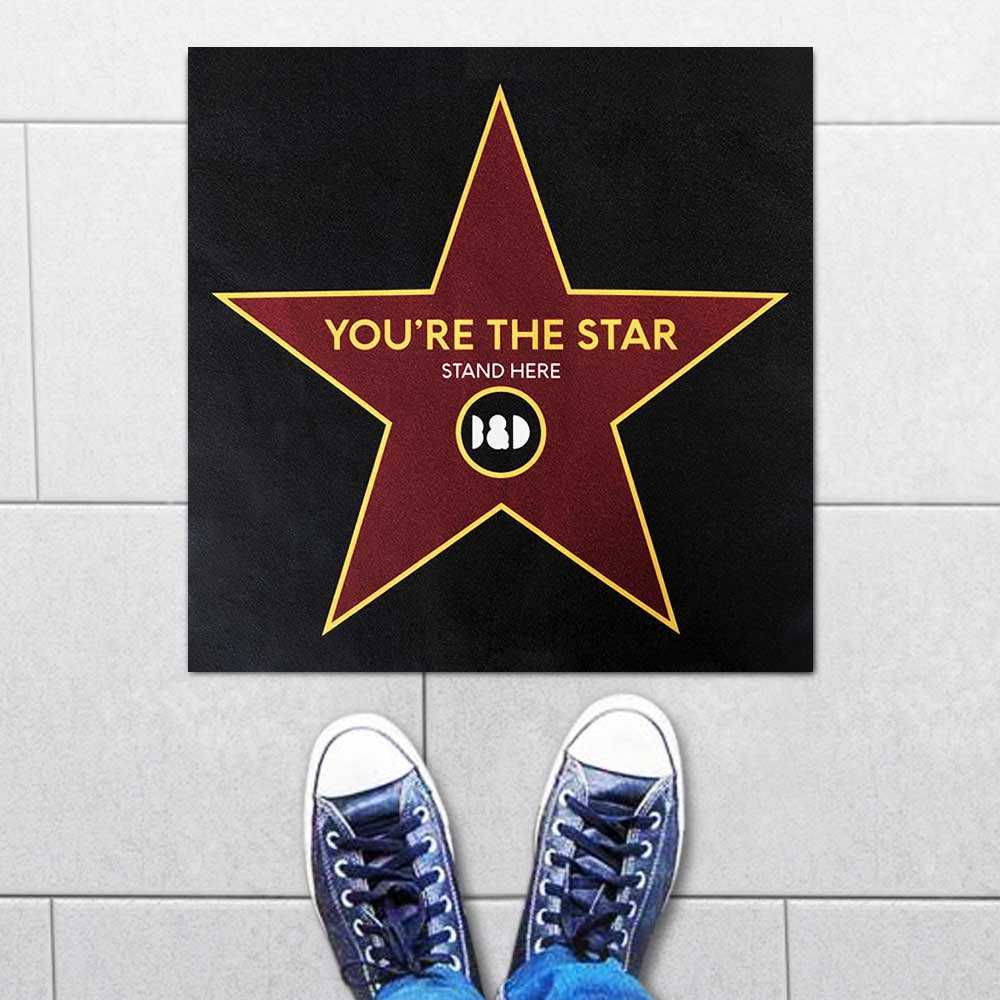

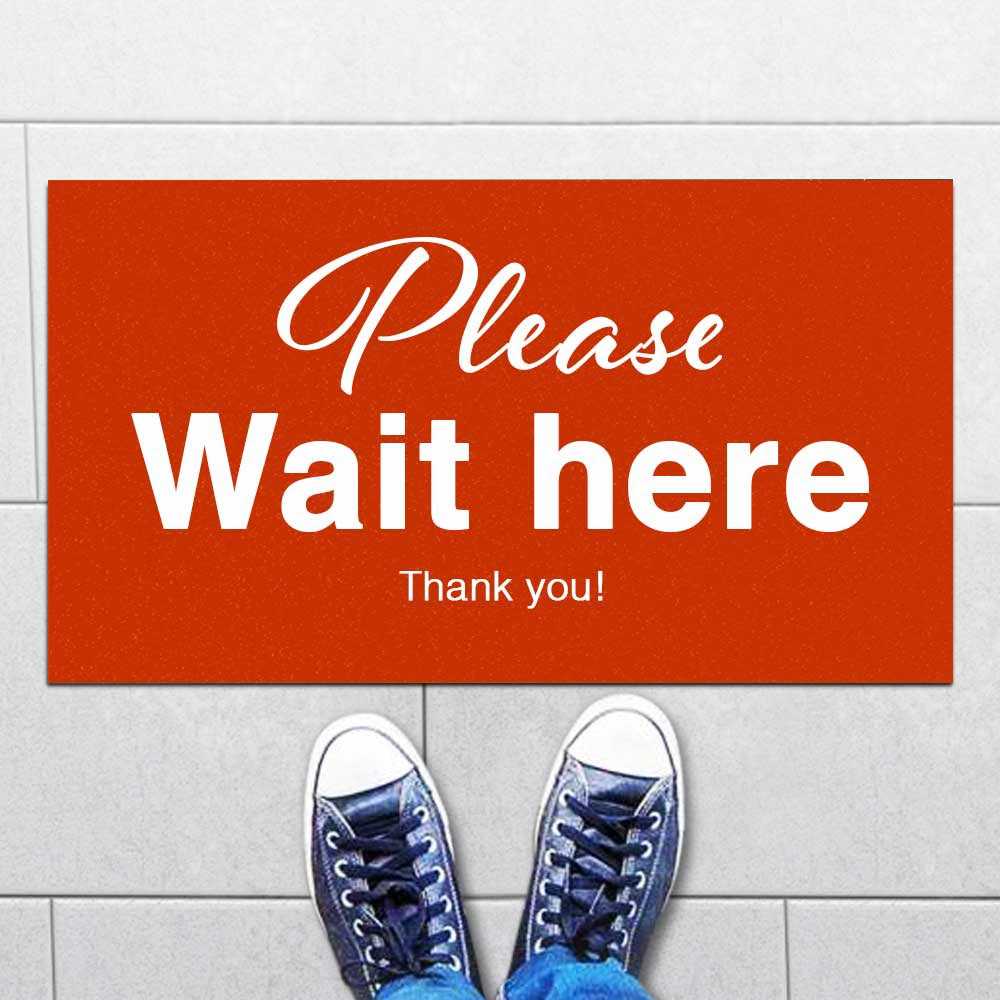

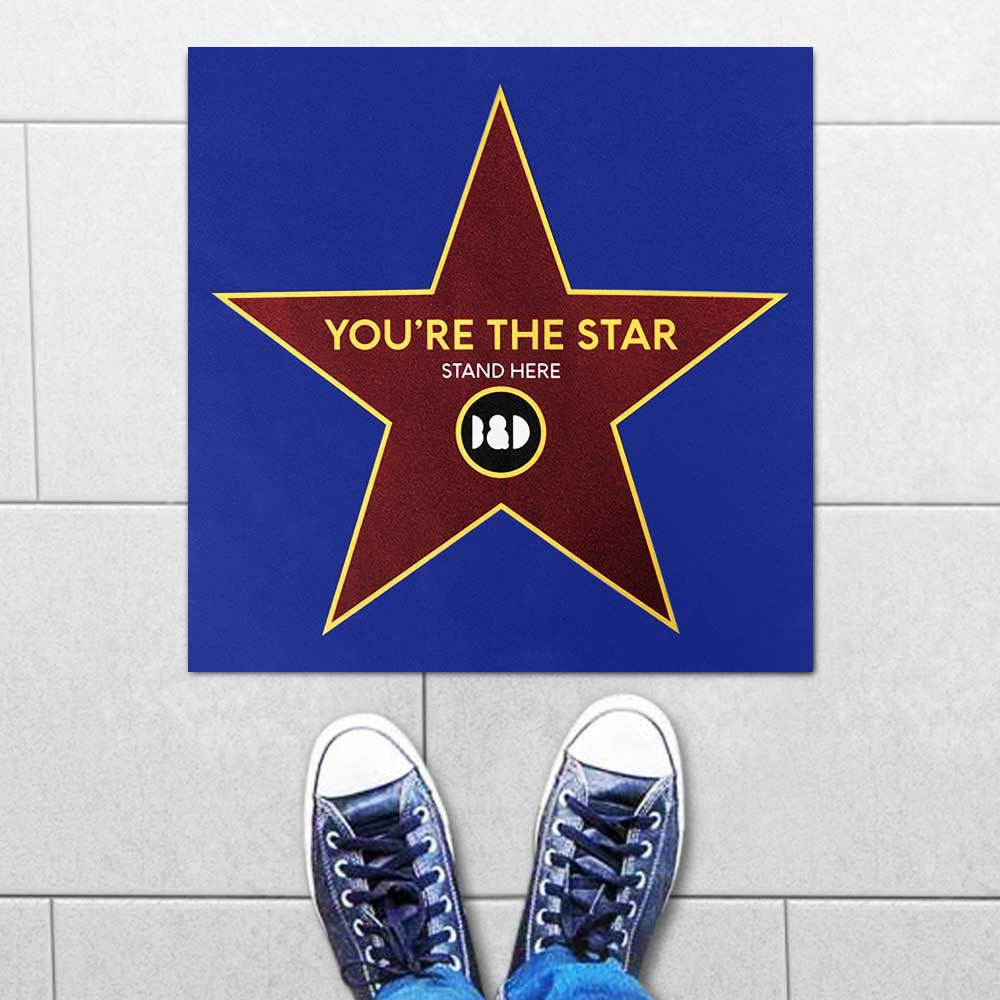

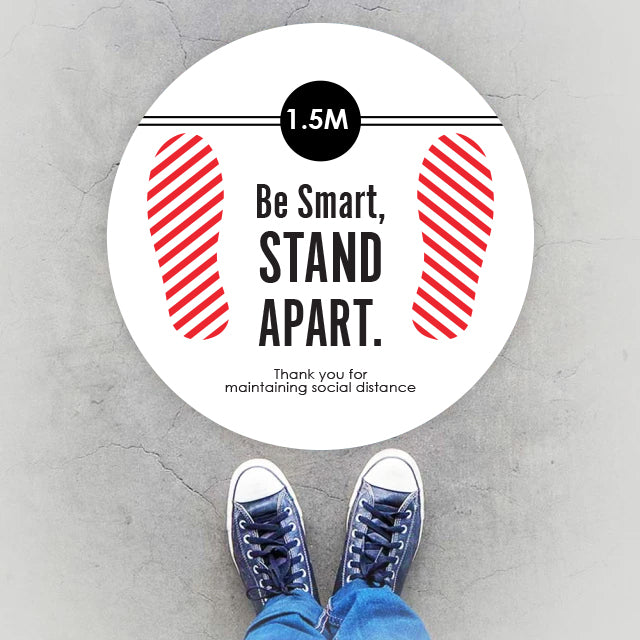

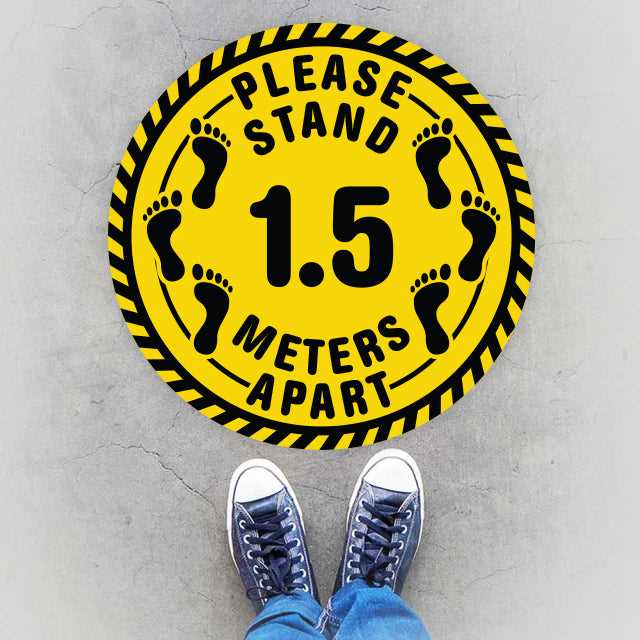

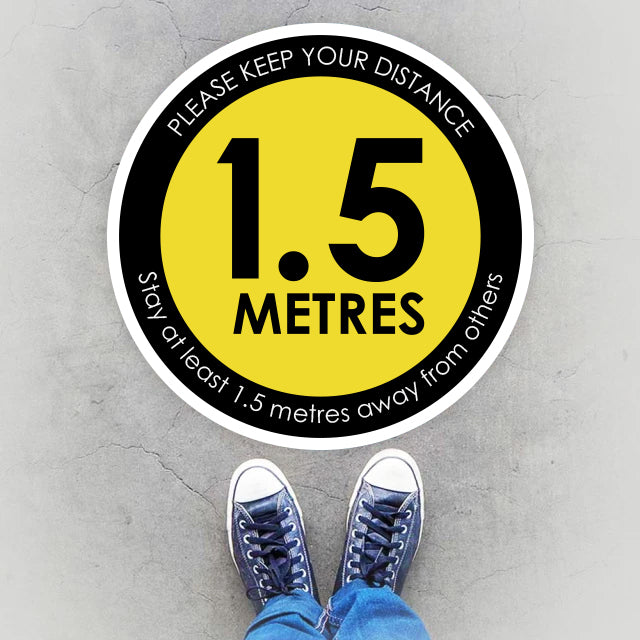

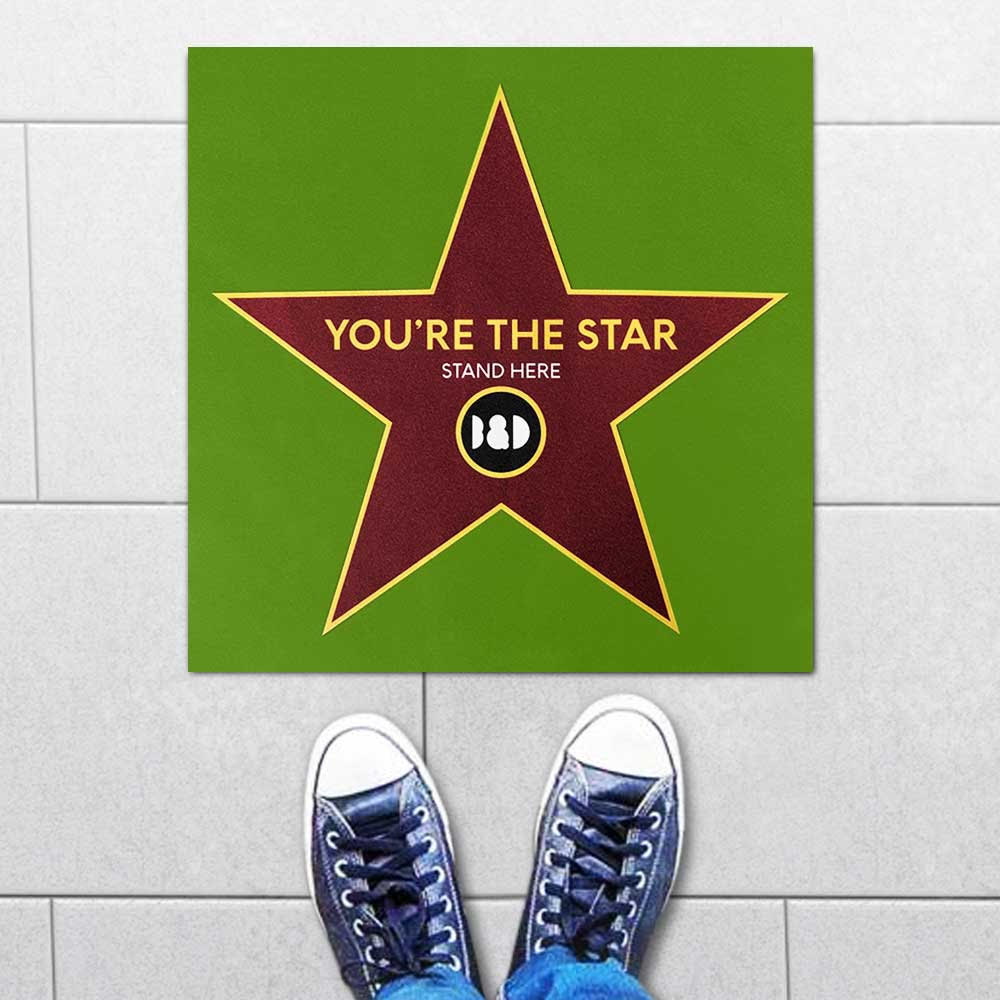

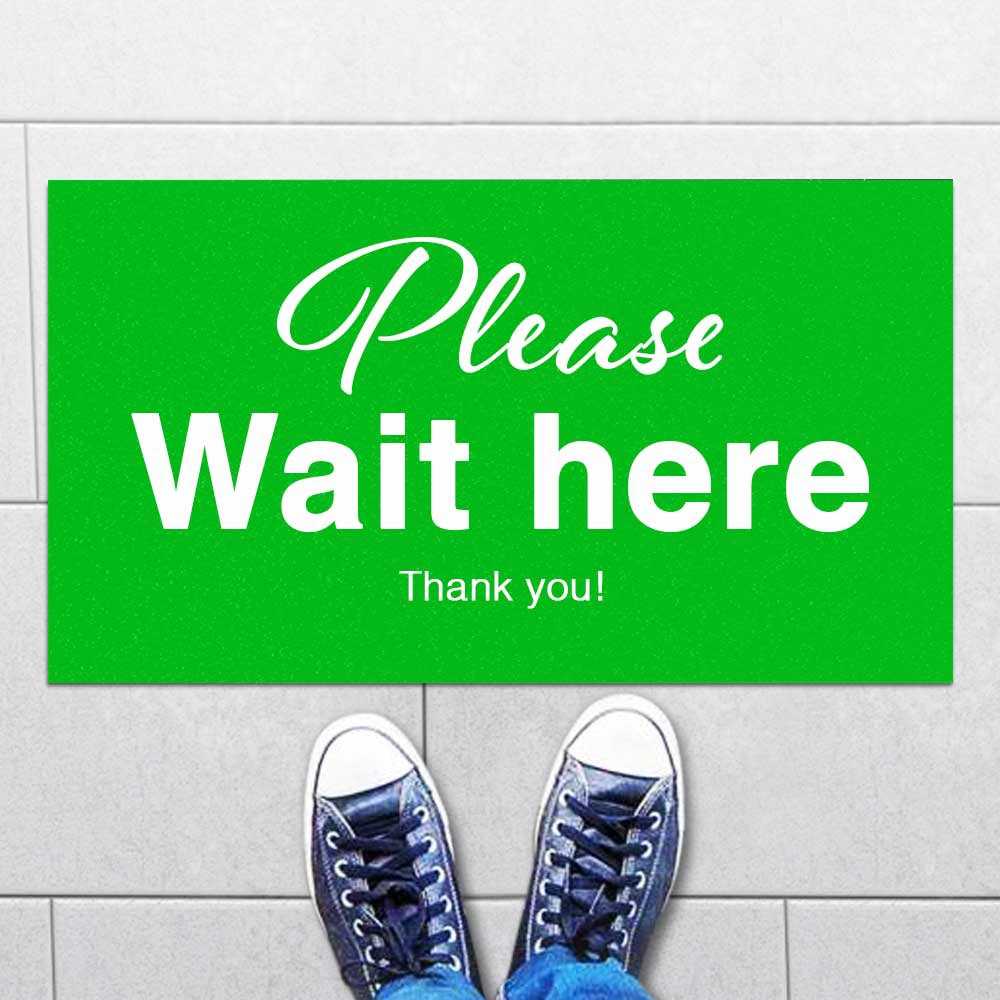

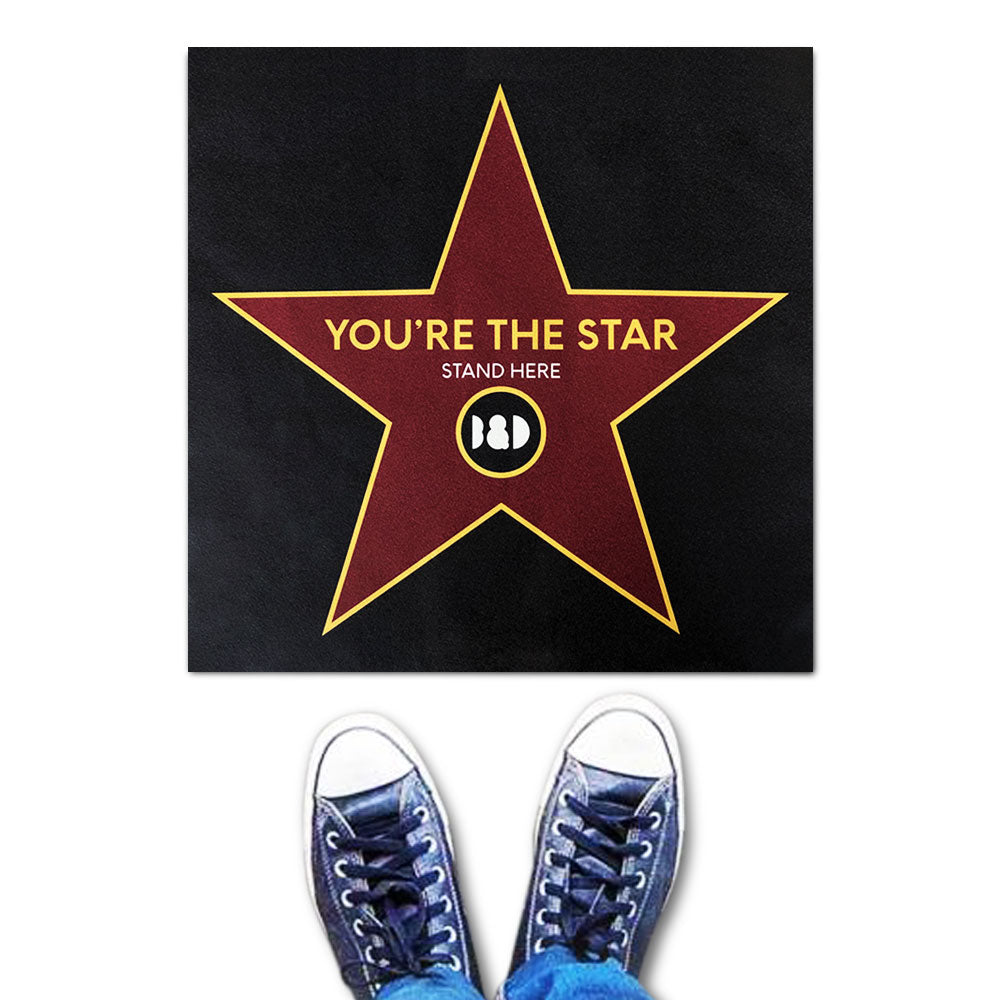

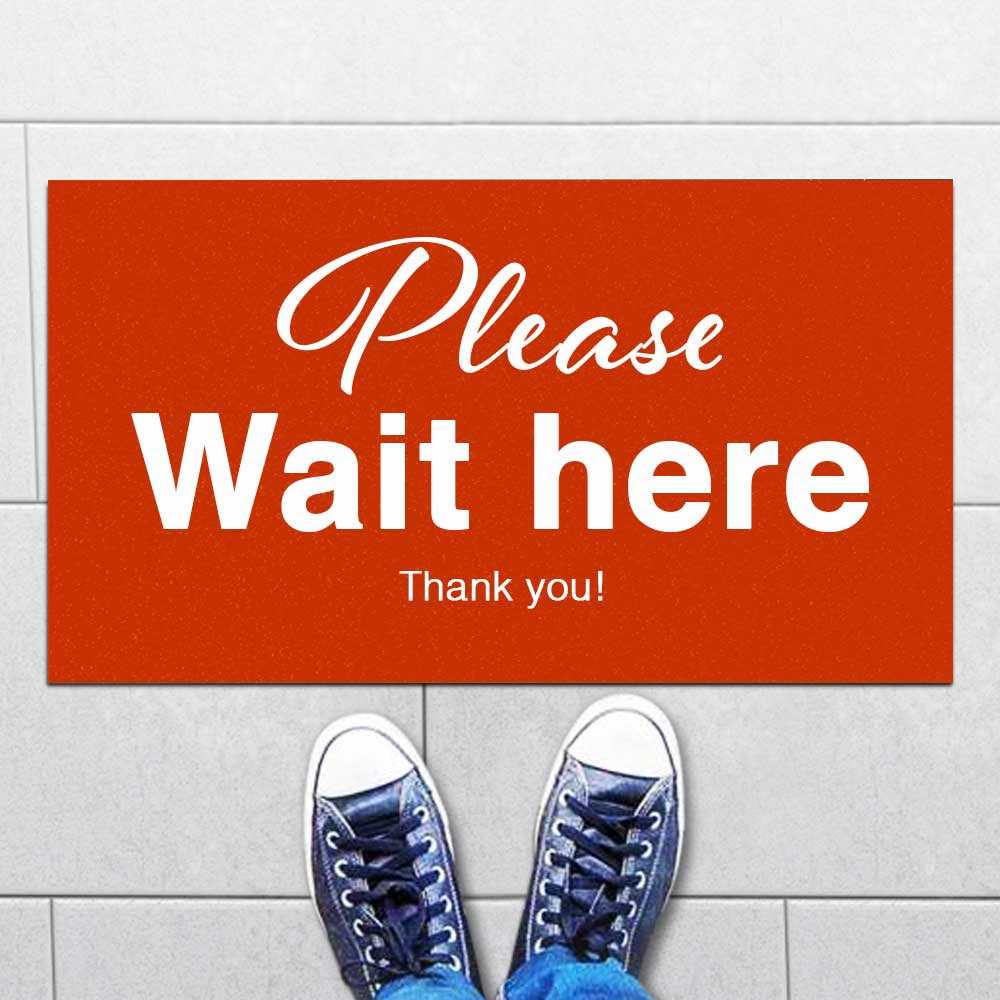

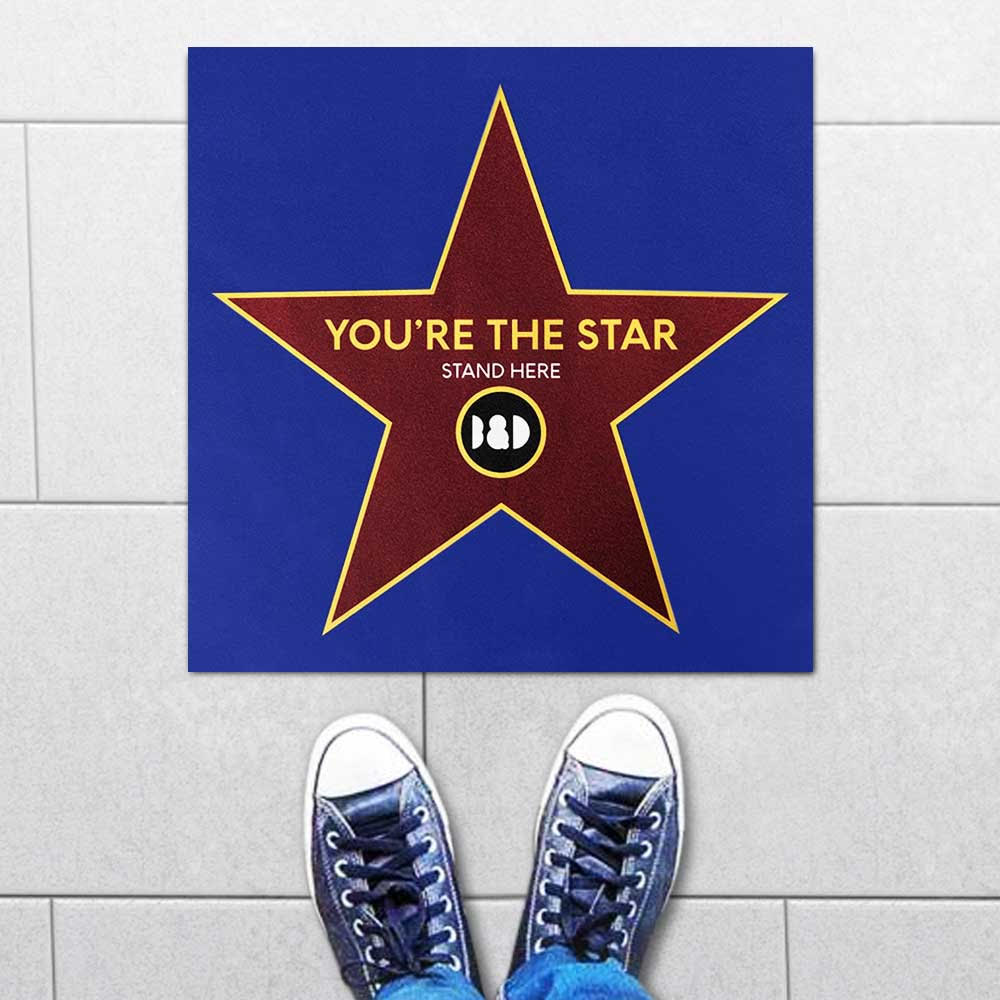

Floor signs and floor stickers can help advertise and convey any message with a straight forward design and eye-catching display. Floor signs are effective for "sale" promotions at trade shows, airport terminal maps, events, shopping malls, interior floors, printed vimy. With the power of visuals on your side - including drawings or illustrations for more artistic styles and large lettering in black and white that's readable from afar - you'll be able to create way finding signs without spending an extra cent!

Place an order online for giant custom floor stickers and buy these personalized floor decals and floor graphics at amazing cheap wholesale prices and huge bulk order discounts for corporate, businesses, events and small businesses. We deliver custom floor signage to all locations Australia wide including Melbourne, Sydney, Adelaide, Darwin, Perth, Brisbane, Gold Coast and Canberra. Get your custom floor signs today.

- Click here to learn about print-ready / press-ready file requirements.

Floor Sign Stickers | Floor Decals - FAQ's

FAQs related to Floor Sign Stickers | Floor Decals

Our process is simple!

1. Select your products

Visit our website and choose your display product.

2. Place your order

Place your order online / phone.

No payment is required at time of placing an order.

3. Artwork Design

You have two main options:

1. Upload your Print-Ready file

2. Let us design one for you

4. Processing

Our team member will be in touch with you to discuss the order further.

5. Proofing

Our designers will email you a digital proof for approval prior to production.

6. Production

Once your artwork is approved, your job is pushed into production.

7. Payment

We will email you a tax invoice requesting full payment ahead of the production of your order.

8. Completion

Once the order is dispatched, we will email you a tracking number confirming the dispatch.

Reviews

Floor Sign Stickers | Floor Decals - Template downloads

- Choosing a selection results in a full page refresh.

- Opens in a new window.